Range of spares include:

High Performance 1100Hv Hybrid Coated Bearing Sleeves / Rings:

To reduce bearing seal-wear and damage. Designed for caster-roll shaft assemblies where a bearing seal makes contact with a metallic surface or shaft. The hybrid structure eliminates ‘peeling’ seen when traditional hard chrome is used. Advantages include no post deposit machining, low micron deposit to achieve 1100Hv hardness, no flaking or peeling and reduced bearing seal damage. Can be used for a variety of components where wear is an issue.

High Performance Dummy Bar Chain Bushes / Pins:

A superior replacement to bronze/brass bushes to give longer operational life without the need to remove or replace. Premtech dummy bar chain system requires NO LUBRICATION to assist with plant environmental policies. References within large European steel producers show lifetime increase of 3-4 times and significant cost and maintenance saving.

CONTINUOUS CASTER SEGMENT PACKERS

Coated Precision Segment Packers for setting roll gap / slab depth - Our precision packers are available for all OEM casters to ensure correct slab thickness is set at points within the caster. Ask for further details.

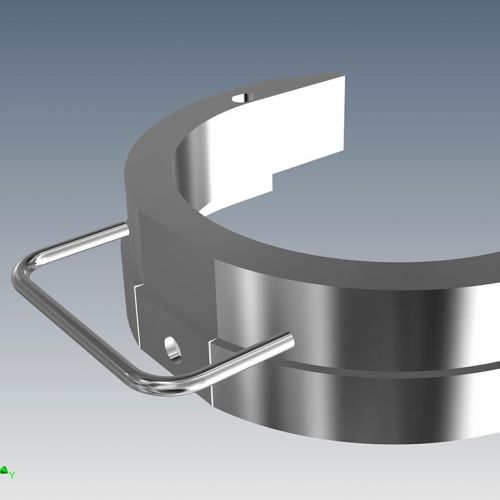

Max-flow Bearing Housings with water channels coated to eliminate internal corrosion and blockages for optimum cooling when casting. Prem-tech retro-fit bearing housings have a unique water bore system to maximise colling efficiency of continuous caster bearings - reducing the risk of bearing overheating, seizing and collapsing. It is critical to maintain optimum conditions of caster bearings via cooling, Prem-tech 'Maxi-flow' housings offer the ultimate solution to reduce breakout risk.

CONTINUOUS CASTER AND MILL SPARES

Difficulty in obtaining caster and mill spares from OEM's? Too expensive with long lead times? Need performance improvement? Ask our team of engineers how we can help with your spares requirement.